Many physics experiments at CERN require moderate magnetic fields (around 2 tesla) in a large gap over a large volume. These are currently created by normal-conducting, iron-dominated electromagnets. While robust and reliable, these resistive magnets require significant electrical power – in the MW range – and therefore can be costly to operate.

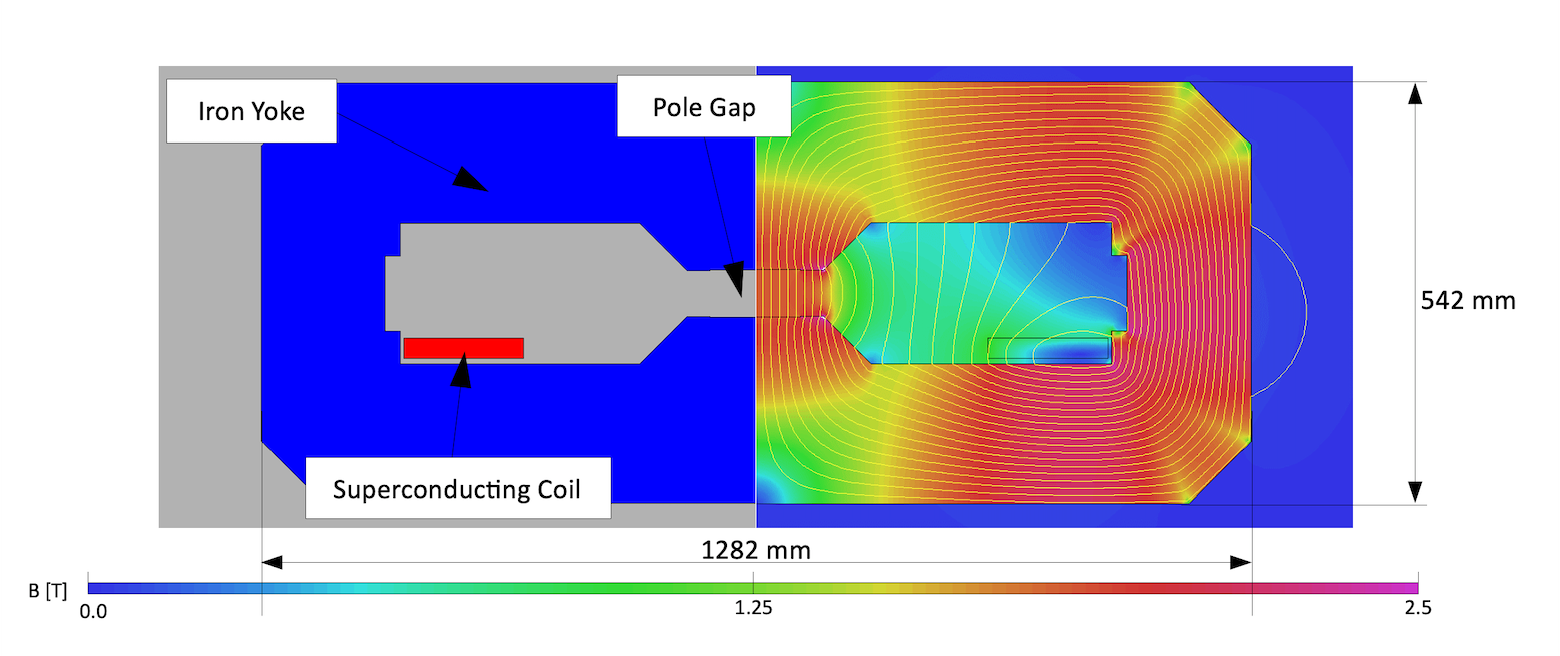

To combat this, engineers from the CERN TE-MSC group are investigating intermediate temperature superconductors (operating at 20 kelvin and above) to be used in the coil winding of electromagnets with the aim of increasing magnet efficiency. They have now designed, manufactured and successfully tested a conductor for use in these electromagnets. This proof-of-principle demonstrator is a superconducting coil wound from a magnesium diboride (MgB2) cable mounted inside an iron yoke. As a first step, the demonstrator was tested at 4.5 K, where it reached the expected magnetic field. The group designed the demonstrator to be easily scalable to large, iron-dominated electromagnets, such as some of the magnets needed for the Search for Hidden Particles (SHiP) experiment. The innovative design could also be retrofitted to existing magnets by replacing the normal-conducting coils with the new coils.

The MgB2 cable is one of the units manufactured for the Superconducting Link of the High-Luminosity Large Hadron Collider (HL-LHC) at CERN. The MgB2 strands were developed by CERN together with ASG S.p.A during the R&D phase of the HL-LHC Cold Powering work package and were produced by ASG S.p.A. The MgB2 cable was also developed by CERN and then industrialised for production in long lengths by Tratos Cavi S.p.A, a member of the ICAS consortium. The iron yoke and the winding formers were fabricated with the support of CERN EN-MME.

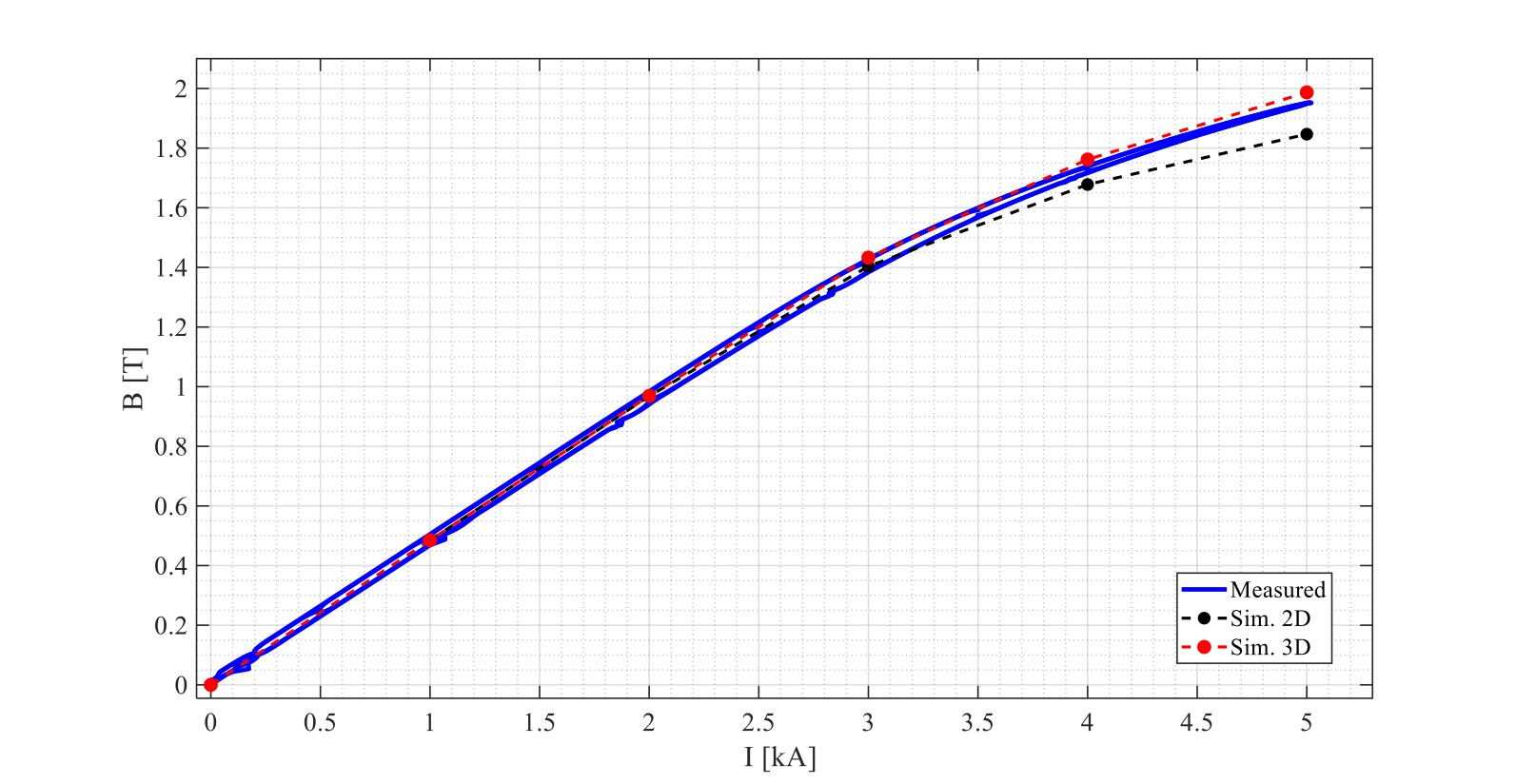

For the initial test, the engineers cooled the demonstrator down to 4.5 K with liquid helium and successfully ramped it up to 5 kA, the design current, without any resistive transition or resistive voltage across the coil. They then warmed it up to room temperature and cooled it again to 4.5 K: the magnet again reached the target current of 5 kA after this thermal cycle, with no quench. Magnetic measurements at cryogenic temperature confirmed that the demonstrator met design expectations, both in terms of field strength – the magnetic field in the pole gap is 1.95 T at 5 kA – and field quality.

“These encouraging results demonstrate the robustness of the MgB2 cable and the suitability of its coil design for iron-dominated electromagnets,” explains TE-MSC group leader Arnaud Devred. “The team warmly thank Richard Jacobsson for inspiring this work, Davide Tommasini for his exploratory feasibility study and José Miguel Jimenez for his unconditional support for this project.”

The next step for the team is to work with the CERN TE-CRG group to carry out a test of the demonstrator in gaseous helium at 20 K. Ultimately, the coil will be inserted into a dedicated cryostat to enable its operation at 20 K while keeping the surrounding iron yoke at room temperature.